Description

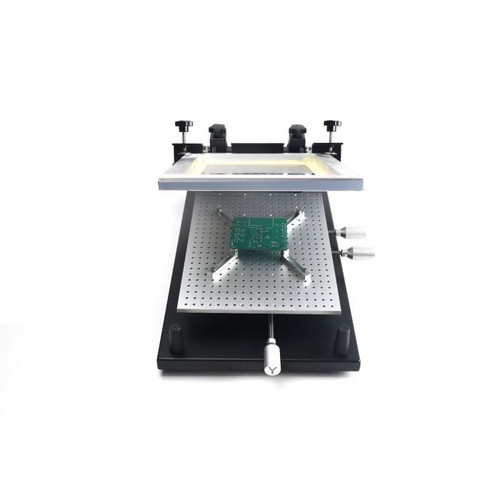

Neoden sets the standard for manual tabletop stencil printers for prototyping and small batch production. The manual stencil printer enables rapid prototyping of PCBs in-house and will deliver a decrease in time and expense compared to out-of-house operations. These stencil printers work with a wide variety of PCB sizes in either single or double-sided configurations. Neoden printers feature a robust design in a compact size that’s easy to configure and use. They are ideal for operations on a tight budget. FP2636 manual stencil printers are part of a Neoden turn-key PCB design and production system that includes SMT Pick and Place machines, production conveyors and reflow ovens. Using the Neoden system you’ll achieve quality, time-efficient results with maximized throughput.

Features

- Compact size for tabletop operations

- Appropriate for single and double-sided PCBs

- Adjustable antiskid rubber feet enable fixture leveling and provides stability during paste application

- X-Y-Z axis user adjustments for fine stencil alignment to the PCB

- Quality stainless steel components holds registration pass-after-pass

- No pneumatics required

What’s in the box?

- Stencil Printer

- Tool kit with 5 PCB guides that mount to the stainless steel table with cap screws. PCBs then mount on the guides using the 35-pin assortment in 1/1.5/2/2.5/3mm sizes.

- 4 inch hand-held solder paste application squeegee

- Paste application pallet knife