Description

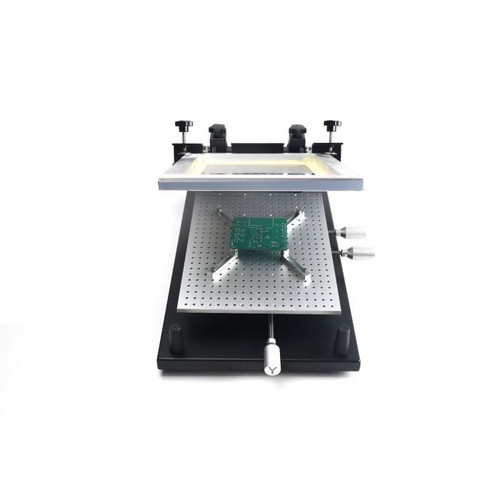

YS Series semi-automatic stencil printers are as simple to program as they are to operate. Use the 5-inch color front panel touch screen to configure a variety of actions for the dual 10-inch squeegees and the pneumatic stencil frame holder. The configuration options include squeegee down pressure for paste application, print stroke travel and print-clean stroke duration along with the cycle intervals. Manual operations include the initial set-up of the vernier print table configuration for x-y-z axis positioning plus consumables replenishment and runtime insertion and removal of the PCB’s. : The YS350 printing table accommodates PCBs up to 600mm x 240mm.

Features

- Stencil single and double-sided PCBs

- Accommodates PCBs up to 600mm x 240mm

- Works with a range of paste formulations and PCB sizes

- Stainless steel table construction holds registration pass after pass

- Microprocessor PLC controlled

- 5 Inch color touchscreen GUI for simple programming

- Track your print count, cleaning intervals, configure L/R squeegee print and clean routine, set start/stop times and paste application pressure

- 3-axis table alignment for precise registration and stencil to PCB contact

- Emergency Stop can be made at any point in the application cycle

- Park the applicators and gantry fixture for easy visual inspection

What’s in the box?

- Pallet knife for paste application

- Two 10 inch squeegees for paste distribution

- Five table mount PCB locater fixtures with cap head bolts and PCB locating pins

- Fifteen additional flex pins to support larger PCBs. Additional fixtures and flex pin kits are available for panelized PCBs.

- 110V to 220V step-up mains transformer