Description

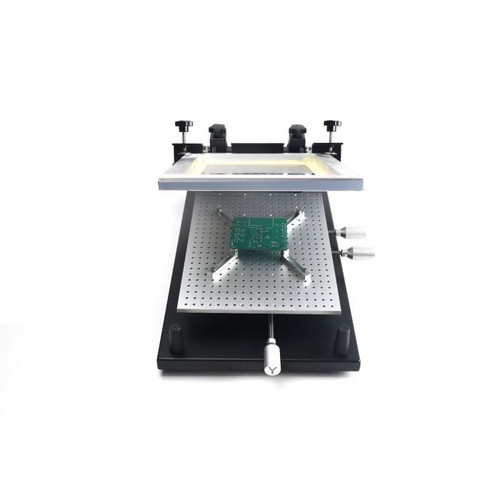

The ND2 optical system is used for two-point fiducial detection on the PCB ensuring proper alignment with the stencil. The camera will detect PCB position and correct worktable X/Y/θ position for best alignment. Fiducial sizes can range from 1mm to 2.5mm and can include standard marks or alternative non-standard shapes that are defined using the configuration application.

The PC system controls squeegee pressure, speed and movement in addition to managing the optical recognition and servo control systems. The B-side PCB cleaning process can be configured for manual or automatic processes including dry or wet with user selectable intervals and handling speeds. The standard printing squeegee width is 300mm and it can be optimized for 45º, 50º or 60º application angles to obtain best stencil penetration and paste transfer to the PCB. Application pressure is selectable from 0.5kg to 10kg with a printing stroke of ±200mm from the center origin position. Available application speed selections range from 0 to 200mm/s.

An annunciator mast is mounted on the top of the machine and provides clear visual and audible alarm anytime the printing process is halted. The machine comes preloaded with the proprietary configuration and control application that provides a complete suite of setup and optimization tools plus real-time productivity tracking.

What’s in the box?

- ND2 Printer

- Monitor, mouse and keyboard

- Annunciator light mast

- Squeegee 300mm x 60mm, 1x

- Top pin kit, A & B types, 10x each

- Eccentric thimbles, 6x

- 250mm & 350mm support pins, 2x each

- Tool kit including wrenches, screwdrivers, assorted replacement fuses, ink pallet knife

and a roll of cleaning paper