Description

Product makers seeking to increase their in-house prototyping and manual feed small batch production capabilities will appreciate this full-featured PnP machine. The YY1 does more and has many big machine features including a Vision System with up and down facing cameras and dedicated front panel video monitors. The touch screen user interface used for configuring the machine is another Neoden exclusive in the compact tabletop machine category. Up your game with an easy-to-implement in-house alternative to outsourcing your prototype and small batch production needs.

Proven Technology

The YY1 is an evolutionary product that has serious heritage. Neoden has years of experience building a wide variety of PnP machines for the electronics industry, universities, research labs, and creative shops. We have applied our deep knowledge of machine design and production best practices to deliver the kinds of features and performance that enable creative makers of all skill levels to bring their prototyping and small-batch manufacturing projects in-house.

Features

- Placement head with two independent placement nozzles

- 3-position nozzle changer accommodates two working nozzles and one parking position

- Component feeder options include tape reel, vibration stick, waffle tray, bulk tray

- Easily handle small components starting with 0201 up to 18mm square body

- Numeric readout of nozzle vacuum for the most reliable component handling

- Convenient touch screen GUI programming

- Dual up/down camera vision system with dedicated video monitors ensures high accuracy

- Internal pneumatic supply

- 110VAC mains operation with external PSU

- Eligible for UPS Ground shipping

What’s in the box?

- YY1 PnP machine

- External PSU

- Acrylic panels and hinged hood

- Maintenance and calibration tool kit

- Starter nozzle kit

- 7” machine mounted tape reel feeders

- 13” external stand for large tape reels

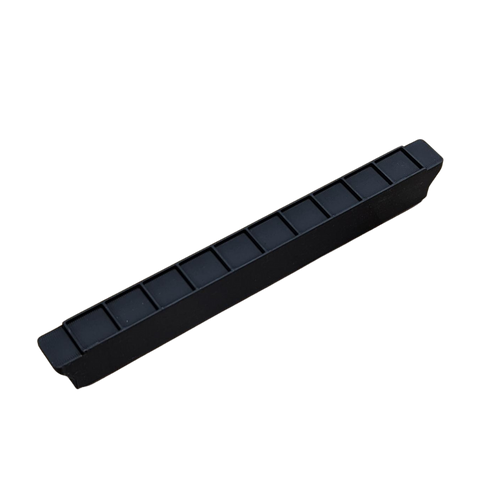

- PCB mounting blocks and support pins

- SD card